INDUSTRIAL WET

SCRUBBER

SCRUBBER INTRODUCTION

An industrial scrubber system is used to clean polluted air or exhaust gases generated by industrial processes before they are released into the atmosphere. It helps industries meet environmental regulations, protect worker health, and reduce damage to equipment and surroundings.

The principle operation of an industrial wet scrubber system is air-pollution control equipment that removes contaminants from exhaust gas streams by contacting them with a liquid (usually water or a chemical solution). They’re common in power plants, chemical processing, metal finishing, cement, pulp & paper, and waste incineration.

The dirty gas enters the scrubber → contacts liquid droplets → pollutants transfer into the liquid → cleaner gas exits.

Scrubbers absorb or chemically neutralize gases such as:

-

Sulfur dioxide (SO₂)

-

Hydrogen chloride (HCl)

-

Hydrogen fluoride (HF)

-

Ammonia (NH₃)

-

Chlorine (Cl₂)

SYSTEM

VENTILATION ARCHITECT

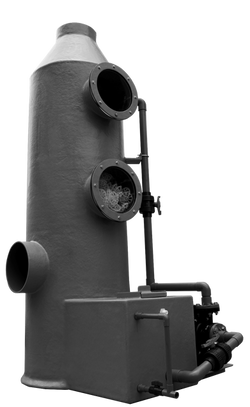

IWS PP 2400 Serises (INDOOR)

IWS PP 1500 Serises (INDOOR)

IWS FRP 2400 Serises (OUTDOOR)

STRUCTURE AND CONSTRUCTION

The rigid housing is moulded from corrosive resistant PP or FRP material. Viewports are provided for inspection, maintenance and repairs if necessary. The sump tank is constructed of the same material and the capacity suitable for recirculation. Neutralising solution, (alkali) can be added if required, but the liquid discharge shall not be toxic to the environment. The spray nozzles are full cone water jet spray 1/8 in. with flow rate of 1.1 l/min at 20 psi. A normally closed solenoid valve controls the incoming water supply.

Additional Accessories :-

1) Flow meter

2) PH Meter

3) Dossing Pump

4) Dossing Tank

5) Pressure Gauge (Analog /Digital) for Body, Packing & Mist Eliminator

Model & Coverage Air Flow

IWS PP 1500 Series - Cover up to 2000 cfm

IWP PP 2400 Series - Cover up to 4000 cfm

IWP FRP 2400 Series - Cover up to 4000 cfm

> 4000 cfm custom model

FEATURES HOOVER / CLICK AT SCRUBBER TO REVIEL MORE INFO

Model refer : IWP PP 2400 Series

Reservoir Water tank have easy access for maintenance, equip with back up fresh water supply, over flow & discharge point.

Tower Packing a unique patented toroidal helix design that makes them dramatically more efficient than conventional packings in a wide range of mass transfer and particulate collections applications

High solid particle loading

Constantly renews and exposes liquid to the gas flow

High efficiency

Injection moulded Polypropylene

Big & Clear View Port for easy monitoring

PP Welding Construction for Scrubber Body

Chemical Resistance Water Pump

Full control of the volume water volume to nozzle

Reservoir Tank equip with filter system

SCRUBBER DESIGN

Air Flow Movement

|  |  |  |  |  |  |  |  |

|---|---|---|---|---|---|---|---|---|

|  |  |  |  |  |